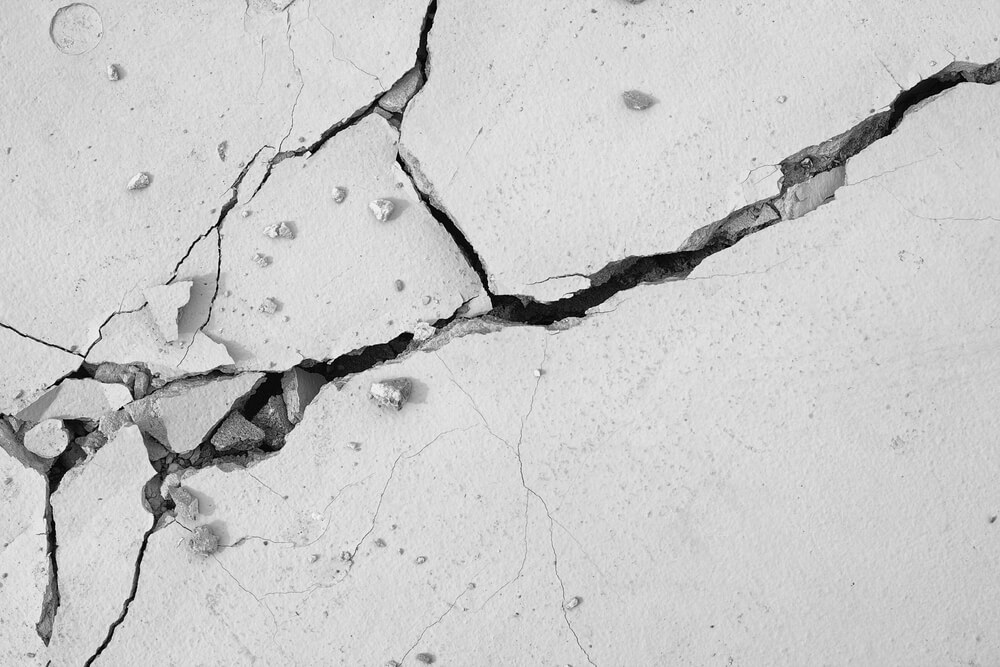

You’ve likely walked on a concrete sidewalk or driveway and noticed a series of cracks on the surface. If you’ve wondered why this happens, you’re not alone. Understanding why concrete cracks can be crucial for construction, renovation, and maintenance.

This guide will provide a comprehensive overview of the reasons behind concrete cracking and offer some preventative measures that can be taken to minimize these issues.

The Nature of Concrete

Concrete is a popular construction material known for its strength, durability, and versatility. It is a composite material made up of water, cement, and aggregates like sand and gravel. However, it is not a static material; it undergoes a series of chemical changes during the curing process, making it susceptible to cracking.

Forces Acting Against Concrete

Temperature and Humidity

One of the most common reasons concrete cracks is due to changes in temperature and humidity. Concrete expands and contracts with temperature fluctuations. Humidity plays a similar role: the material can absorb moisture, leading to expansion, and lose moisture, resulting in contraction. When the concrete is unable to expand or contract freely due to external restraints like adjacent structures or the ground itself, cracks may form as a result.

Structural Overload

Another contributing factor is structural overload. This occurs when the weight or stress placed upon the concrete exceeds its strength, leading to cracks. For example, heavy vehicles or machinery on a concrete driveway can cause the material to crack if the slab has not been designed to handle such loads.

Ground Restraint

The ground upon which the concrete is laid acts as a natural restraint against its movement. Earth’s solidity and texture prevent the concrete from expanding or contracting as much as it would like, contributing to the occurrence of cracks. In particular, soil types with poor drainage or expansive properties can exacerbate this issue.

Measures to Prevent Cracking

Proper Design and Construction

To minimize the incidence of cracks, it’s crucial to follow best practices in concrete design and construction. For instance, using the right mix of concrete for the specific application can help improve its resistance to cracking. Likewise, reinforcing the concrete with steel bars or mesh can also enhance its structural integrity.

Control Joints

Strategically placing control joints can allow the concrete to crack in specific, less noticeable areas. These joints provide weakened planes where the concrete can safely expand and contract, minimizing random cracking.

Post-Construction Care

Regular maintenance, like sealing cracks as soon as they appear and ensuring proper drainage, can help prolong the life of the concrete surface and limit further cracking.

Conclusion

Understanding why concrete cracks is the first step in effectively dealing with this common issue. Factors such as temperature changes, structural overload, and ground restraints contribute to cracking. However, proper design, construction techniques, and post-construction care can minimize the appearance of cracks and prolong the lifespan of concrete structures. With this knowledge, you’ll be better equipped to manage and maintain concrete surfaces effectively. Contact Richfield Concrete today to learn more about why concrete cracks.